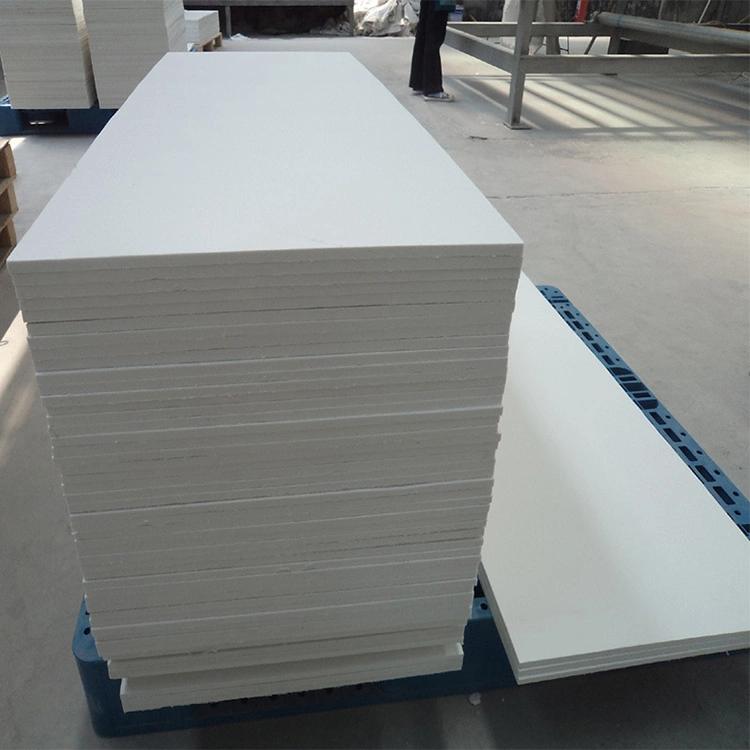

Fireproof Thermal Insulation Board Sealing Ceramic Fiber Calcium Silicate Plate

Basic Info.

| Thickness | 25mm-120mm |

| Appearance | Panel |

| Color | White |

| Material | Non-asbestos |

| Type | Fibre Board |

| Surface Finishing | Smooth |

| Edge | Square |

| Shape | Square |

| Refractory Temperature | Over 2000 ℃ |

| Usage | Furniture, Building |

| Working Temperature | 1100c/1260c/1360c/1430c |

| Feature | Good Thermal Insulation |

| Sample | Avaliable |

| Keyword | Calcium Silicate Boards |

| Certification | ISO CE |

| Width | Customizable |

| Length | Customizable |

| Application | Building and Industry, Refractories, E |

| Product Name | Calcium Silicate Board |

| Transport Package | International Standard |

| Specification | Customizable |

| Trademark | RONGSHENG |

| Origin | China Rongsheng |

| HS Code | 68061010 |

| Production Capacity | 5000t Per Year |

Packaging & Delivery

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 600.000kgProduct Description

Fireproof Thermal Insulation Board Sealing Ceramic Fiber Calcium Silicate Plate

Product Description

Features Of Calcium Silicate Board

Calcium silicate board main material of the products are SiO 43%, CaO 44% and reinforcing fiber. The products are made by stirring, heating, gelling, forming, pipe hardening and drying. With light bulk weight, Low thermal conductivity and high bending and compressive strength character, using in construction.Petroleum, electric power and Building partition wall, curtain wall, roof and building envelope thermal insulation.

Feacture of Polycrystalline Mullite Fiber Board:

Obvious cooling :As a backing insulation materials,they have a very marked effect of energy consevation,as a result of less accumulation of heat and bigger heat protection.Good durability:After long used,the boards do not shrink,out of shape and turning powder out,insulation performance does not decline.High rate strength:The rate strength of calcium silicate board is the highest in the thermo inorganic material.During the design,it can lighten the all-up weight of the kiln and stove greatly.Easy construction:Using common woodworking tools can be cut to any necessary form,and can be glued and formed with other materials easily.Environmental protection:No corrosives and toxicity,there are not exhaust gas and peculiar smell under the high temperature,will not cause the injury and pollution to the human body and environment.It's belong to the products of environment protection.

Calcium Silicate Board characteristic:

1. Low thermal conductivity,good thermal insulation.2. Low heat Shrinkage, good thermal stability.resistance to most of the erosion.3. Water bearable,keep constant performance after drying.4. Light weight, high compressive strength ,easy installation.5. Safely in use and non-toxic,no poisonous substance,free of asbestos.

Applications Of Calcium Silicate Board

electrical equipment heat insulationmetallurgical equipment heat insulationglass furnace equipment heat insulationall kinds of furnace body heat insulationCement kiln heat insulationShipyard cabin heat insulationpetrochemical industry heat insulationRegenerative Heating Furnace thermal insulation Industrial coke oven heat insulation

Technique Data of Calcium Silicate Board

Calcium Silicate Products | RS-CS650 | RS-CS1000 |

Density(KG/M3) | 170/220/280 | 170/220/240 |

Compressive strength(MPa) | ≥0.35 | ≥0.35 |

Thermal conductivity (average temperature 70 ºC) W/m.k | 0.052 | 0.048 |

Maximum temperature(ºC) | 650 | 1000 |

Linear shrinkage(%) | ≤2(650,3hrs) | ≤2(1000,3hrs) |

It can be processed into a shell and tube or curved panels according to customer requirements. | ||

Detailed Photos

Product Application

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + cartonFor example, Standard size of Fireclay brick : 230x114x65mmShipping : 384pcs/plt x 18plts in one 20 feet container;

Company Profile

RS Refractories Co., Ltd. is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.RS Refractories Co., Ltd. is a first-class supplier of refractory materials, we can provide you with the most advantageous quotations and products. Looking forward to be your partner!

Certifications

FAQ

Q1. Are you Manufacturer?

A: Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.Q2. Can we visit your company?

A: Sure,welcome at any time,seeing is believing.Q3. Do you accept OEM?

A: Yes, we can do OEM.Q4. What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your condition.Q5. What are the payment terms?

A: Usually T/T,but L/C,Western Union etc are available for us.Q6. How long is delivery time?

A: The delivery time will be determined according to the quantity of the order.Q7. How are your products' quality?

A: The products will be strictly inspected before shipment, so the quality could be guaranteed.Q8. How to solve the quality problems?

A: If the products are not confirmed to customer samples or have quality problems,our company will be responsible to make compensation for it.Q9. What is the service life of your bricks?

A: The service life of different bricks is unlike.It also depends on your using condition and method.Q10.How about your company's certification?

A: ISO9001 and Test Report,also we could apply other necessary certification.